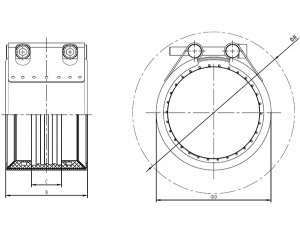

Axially Restrained With Double Anchor Rings Coupling

The GRIP-G coupling is designed to replace the need for flanging, welding, pipe grooving and pipe threading by providing a quick and easy solution to joining plain-end pipe. The GRIP-G has two anchor rings which are placed adjacent to, but separate from, the sealing mechanism.

Suitable for pipes sizes from O.D φ26.9 to-φ273mm.

Suitable for pipes material: Carbon steel, stainless steel, copper, cunifer, cast and ductile iron, GRP, most plastic and other material.

GRIP-G Axially restrained with double anchor rings coupling is the most popular type in GRIP Coupling series. Two anchor rings have progressive anchoring effect, it is easy on pipes, as pressure increased, so does the gripping effect. GRIP-G offers high levels of security by locking pipes together under pressure. GRIP-G working pressure up to 46 bar. Temperature range: -30℃ up to 180℃, material in SS304, SS316 and SS316TI. It suitable for most applications in shipbuilding, offshore industries, water and waste treatment, industrial process pipe work and others.

GRIP-G Technical parameters

GRIP-G Material Selection

| Material / Components | V1 | V2 | V3 | V4 | V5 | V6 |

| Casing | AISI 304 | AISI 316L | AISI 316TI | AISI 316L | AISI 316TI | |

| Bolts | AISI 304 | AISI 316L | AISI 316L | AISI 304 | AISI 304 | |

| Bars | AISI 304 | AISI 316L | AISI 316L | AISI 304 | AISI 304 | |

| Anchoring ring | AISI 301 | AISI 301 | AISI 301 | AISI 301 | AISI 301 | |

| Strip insert (optional) | AISI 301 | AISI 301 | AISI 301 | AISI 301 | AISI 301 |

Material of rubber gasket

| Material of seal | Media | Temperature range |

| EPDM | All quality of waters,waste water, air, solids and chemical products | -30℃ up to+120℃ |

| NBR | Water,gas, oil, fuel and other hydrocanbons | -30℃upto+120℃ |

| MVQ | High temperature liquid, oxygen, ozone, water and so on | -70℃ up to+260℃ |

| FPM/FKM | Ozone, oxygen, acids,gas, oil and fuel (only with strip insert) | 95℃up to+300℃ |

Benefits of GRIP Couplings

1. Universal use

• Compatible with any traditional jointing system

• Joins pipes of the same or dissimilar materials

• Quick and simple repairs of damaged pipes without service interruptions

2.Reliable

• Stress-free, flexible pipe joint

• Compensates axial movement and angular deflection

• Pressure-resistant and leak-proof even with inaccurate pipe assembly

3.Easy handling

• Detachable and reusable

• Maintenance free and trouble free

• No time-consuming alignment and fitting work

• Easy installation technology

4.Durable

• Progressive sealing effect

• Progressive anchoring effect

• Corrosion resistant and temperature resistant

• Good resistant to chemicals

• Long service time

5.Space-saving

• Compact design for space-saving installation of pipes

• Light weight

• Needs little space

6.Fast and Safe

• Easy installation, no fire or explosion hazard during installation

• No cost for protective measures

• Absorbs vibration /oscillations